Technical supportúXiamen 12T Network Technology Co. Ltd. Talent supportu :Xiamen Talent Network

Technical supportúXiamen 12T Network Technology Co. Ltd. Talent supportu :Xiamen Talent Network

A, compilation basis

"Building construction safety inspection standards" JGJ59-2011;

The construction fastener type steel pipe scaffold safety technical specifications "(JGJ130-2011)

Working in the construction of higher safety technical regulations (JGJ80-2011)

"Regulations of technology of mechanical equipment to the construction site inspection (JGJ160-2008)

The construction safety technical specification template JGJ162-2008;

The construction site temporary electrical safety technical specifications "(JGJ46-2005)

Design drawings

Construction organization design

Stone stone5A study club

Second, the project summary

MaShang Town ma shang village resettlement village northeast north 3 # building engineering construction unit for zibo is MaShang Town horse is northeast village, the villagers' committee, the design unit for the zibo city planning design and research institute, prospecting units for the taian chemical geological engineering investigation institute, supervision company for the shandong the engineering project management co., LTD., the construction total package unit of shandong royal construction co., LTD.

MaShang Town ma shang village resettlement village north 3 # residential building is located in the northeast is located east of zibo is Beijing road, new road, south of the project for the shear wall structure, 29 layer on the ground, underground 3 layers, height 87.0 meters, a total construction area of 25202.65 square meters.The project cost 29.13 million yuan.

One to three layers (elevation of 1.2 m to 9.0 m) wall USES marble wall, the floor type steel pipe scaffold, continuous set up along the wall.

Three, the erection

1, the material preparation

(1) stow-wood by 6 m * 0.2 m * 0.2 m board

With a diameter of 150 mm (2) base, to 8 mm thick circular pad iron.

(3) the steel pipe using A3 steel, 48 mm diameter, 3.0 mm thick arms.

(4) fasteners right-angle fastener, docking fastener, rotating fastener.

(5) safety net: flat screen, set net are all provinces shall apply mutatis mutandis to recommend products, have a certificate of approval, recommend use card, apply certificate, and the test of zibo Arabian detection co., LTD.

(6) scaffold board USES: board of 3 m / 6 m long, 0.25 m / 0.30 m wide.

2, name and quantity of all kinds of materials

The name of the

The number of

The name of the

The number of

The name of the

The number of

Flat screen

80 pieces

Frame tube

2300m

Right-angle fastener

800

Nylon rope

900m

Even the wall

100

Diagonal fasteners

180

Set net

300 pieces

The base

120

Corner fastener

150

3, the personnel to carry out the

Frame work of this project all related certificates, scaffolder 3 people, by the whole process of full-time security officer is responsible for set-up and dismantle scaffold, and check the scaffold in the construction process each link in a timely manner.According to the project specific conditions, workers all related certificates, basic meet engineering needs.

Four, the erection steps

1, the erection parameters

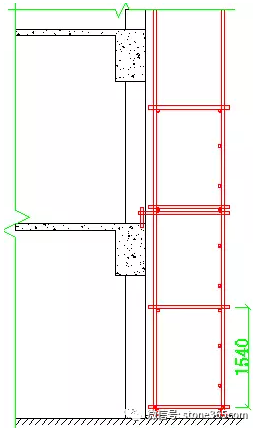

Double-row scaffold erection of height of 11.5 m, the vertical distance of 1.55 m, horizontal distance of 1.05 m, step distance of 1.54 m;Lateral horizontal pole, on lap on the longitudinal rod lateral horizontal pole number for 3 root;The bent frame from wall 150 mm;Even wall with two step three spans (meet humanly scaled mouth are set, plus a brace when necessary), double fastener connection;AnQuanPing network laid 2 layer (a layer and operation layer).

2, process flow,

Stud base compaction and hardening treatment to drain, positioning - plate - stand on both sides of poling, sweeping bar, lateral horizontal pole, longitudinal bar (or temporary transverse and transverse horizontal bar) to stand behind support - > tree middle pole, lateral horizontal pole, longitudinal rod, protective railings to step and so on, forming a closed frame body, a second frame to pull even the wall piece, cast down the tide - the corner set "of" scissors to hang put dense mesh net, scaffolding plank, connect stud to frame in vitro elevation setting bracing, take the third step frame (bracing and safety net synchronization) - >...To complete.

Set-up step 2,

1), scaffolding set-up, must cooperate with construction schedule should be not more than a build-up adjacent wall more than a step or two.

2), the bottom of the vertical rod 1.2 m wide, 80 thick C15 concrete cushion layer and wood plate, steel base, the base bottom elevation higher than that of natural ground level ground 50 mm, plate length is 6 m, width is 200 mm, the thickness of 50 mm.Base plate shall be accurate in the positioning line.

3) set to sweep the floor bar, longitudinal rod close to the vertical sweeping rod below Settings;And the longitudinal rod sweeps the floor is 200 mm from bottom epithelium.Poling longitudinal distance of 1.55 meters, the horizontal distance of 1.05 meters, step distance of 1.54 meters, the vertical rod is apart from the wall of 0.15 meters, the actual operation can be slightly adjusted according to actual situation.

4), lateral horizontal bar: lateral horizontal pole tied to the longitudinal bar above, extended longitudinal rod length not less than 10 cm;In each stud with longitudinal rod intersection point should be set transverse horizontal rod and node distance is not more than 10 cm.

5), longitudinal bar is located in the medial, length is 6 m, adjacent joints are not in with cross, more than 500 mm and adjacent joints are stagger, joint center within 600 mm from the master node, side against the wall overhanging length is 200 mm.

6), adjacent stud connectors are not in sync, synchronization across a vertical rod inside the two direction staggered joint ground height distance of not less than 500 mm, sub center distance of the master node within a distance of 500 mm.

7), with the step of the enclosed scaffolding, lateral horizontal pole should be around the circle, with rectangular fasteners with inner and outer corner rod fixation.

8), the North Pole along the outer wall long build-up, north wall sunken place along the wall to add a row of stud.Scaffolding poling in south along the outer wall long tower set, concave set into place three rows between the two balcony poling.

9), a temporary stay.Began to take to set up the rod, should every 6 set across a brace, until a stable after installation, the wall shall be removed depending on the situation.

10), even the wall set up: even the wall bar every three step across the second set a (unable to set the window place Settings), close to the master node set, less than 300 mm from the master node, start from the first step in the horizontal level bar set, into inside and outside wall with 500 mm short tube after fastening, both inside and outside the add another antiskid fasteners.

11), bracing Settings: bridging across SiKua five steps, the diagonal near the stud with fastener connection, external oblique rod used lateral horizontal rod sponson connection, Angle of 45 to 60 degrees, bridging two feet on the ground plate, the diagonal to take or move two 6 m pole, lap length not less than 1 m, set three rotating fastener, set-up stud outside the lateral bracing, decorate on scaffolding end corner.Set scissors walked four floor north, the south set scissors walked four, the east of bridging two.

12), the safety set net set poling inside, outside the scaffold with nylon cord tie, juncture is tight, flat screen is apart from the ground 4.5 meters of the first layer network, every 10 meters net between a layer, operation layer with the layer is set on the net, and be put with scaffolding plank.Flat screen binding on the lateral horizontal pole, taut tied tightly.

13), security access point out scaffolding 5 meters, width 1.8 meters, 3.1 meters high, at the top of the fortification hit layer, waterproof layer, spacing of 0.5 meters.

14), scaffolding full shop head, set-up on the longitudinal rail joint, using both lap and butt laying shape, lap joint length is 200 mm, laid out lateral horizontal pole plate end more than 100 mm, docking, laid must set two longitudinal rod joint, scaffolding extending length of 130 ~ 150 mm, two boards overhanging long and 300 mm.

15), scaffolding set-up, must cooperate with construction schedule should be not more than a build-up of adjacent wall more than a step or two.

After 16), and each step of scaffolding, should be stipulated in the standard calibration interval, longitudinal distance, horizontal distance and verticality of stud.

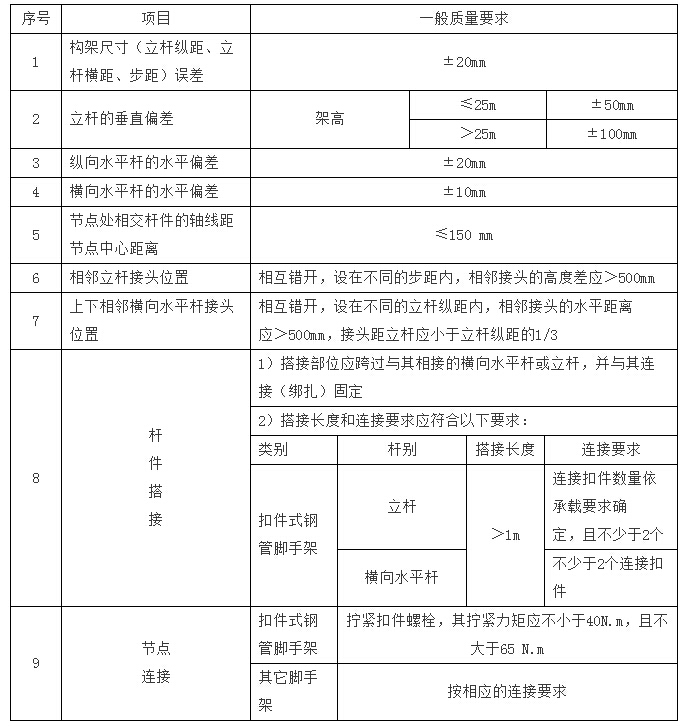

Five, the technical requirements of the scaffold erection and allowable deviation

The technical requirements of the scaffold erection and allowable deviation

Number 2 fastener tighten sampling inspection and quality standard

Six, construction points for attention

1, when the scaffold based equipment foundation, pipe trench, in use should not be in the process of excavation, otherwise the reinforcement measures must be taken.

2, poling extension in addition to the top the top step, the rest of the each layer of each step must adopt butt joint fastener connection.

3, the main node must set a longitudinal rod, buckle with right-angle fastener and it is forbidden to dismantle.

4, scaffolding set-up, must cooperate with construction schedule should be not more than a build-up of adjacent wall more than a step or two.

5, it is strictly prohibited to 48 mm outside diameter mixed with 51 mm steel pipe used.

Set-up should be 6, bracing, transverse brace with stud, vertical and longitudinal horizontal pole synchronous build-up.

7, one word, open rack double-row scaffold of both ends must be set lateral brace.

8, the double row height under 24 m scaffold, must be in the outside facade at each end set a bracing, and set up straight from bottom to top.

9, fastener installation regulations

1), fasteners specification must be the same as the pipe diameter;

2), bolt tightening torque is not less than 40 n. m, and no greater than 65 N.m.

3), the primary node fixed longitudinal rod, rod, scissors, lateral horizontal, horizontal brace in the center of the square buckle, rotating fastener, such as the distance between each other should not be greater than 150 mm;

4), docking fastener openings should be up or itself;

5), the end of the bar out of fasteners on the edge of the plate length should be not less than 100 mm.

Seven, scaffolding, the safety management

1, scaffolding, staff must be after according to the current national standard "special operations personnel safety technical appraisal management rules of examination professional qualified scaffolder GB5036-1985.Mount guard personnel should be regular physical examination, eligible may show certificates.

2, erection of scaffolding workers must wear safety helmet, wear your seat belt, wearing non-slip shoes.

3, scaffolding set-up quality, components quality and acceptance shall be stipulated in the specification for inspection, qualified rear must use.

4, strictly control the construction load, the scaffold shall not focus stacking load, construction load shall not be greater than 2 kn/m2.Shall not be template bracket, cable wind rope, pumping concrete and mortar conveying pipe fixed on the scaffold;It is forbidden to hang lifting equipment.

5, when there are more than 6 and 6 winds and fog, rain and snow weather should stop when the scaffolding, and demolition work.Rain and snow have slippery measure and should sweep the snow.

6, during the use of scaffolding, forbidden to dismantle the master node in vertical and longitudinal rod, vertical and horizontal to sweep the floor, it is forbidden to dismantle the wall.

In July and may not be on the basis of the scaffold and its nearby mining operations, or security measures should be taken, and the competent department for approval.

8, opening on the erection of scaffolding, outer protective measures to prevent falling objects hurtful.

9, electricity, gas welding work on the scaffold, there must be a fire protection measures and personnel guards.

10, scaffold for site erection of temporary electricity lines and grounding, lightning protection measures, etc., and should be according to the current industry standard "construction site temporary electrical safety technical specifications" (JGJ46-2005) of the relevant provisions.

11, the erection of scaffolding, the ground should be set fencing and warning signs, and hold people to keep and prohibit the operation personnel.12, scaffolding poling based lateral should set the drain and the necessary tools, in case of rain water.

13, external scaffolding set-up in distance may not be within the safe distance of overhead line, ground handling and reliable safety.

14, scaffolding must timely maintenance, strong stability, in order to achieve to ensure construction safety.

15, outside scaffolding steel columns, steel wood is forbidden to mix, fasteners, rope, wire, plastic mixture is prohibited.

16, control fastener bolt tightening torque, using torque wrench, torque should be controlled in the range of 40 ~ 65 n. M.

17, it is forbidden to scaffolding probe plate, laid scaffold board and multiple operations, should be as far as possible in the construction of transmission of internal and external load balance.

18, to ensure the integrity of the scaffold and shall not be truncated frame body.

Eight, scaffolding using stage

Should be in accordance with the following phases 1, scaffolding, quality inspection, found that the problem should be timely correction.

1) before the scaffold erection;

2) before the operational load;

3) after the heavy rain;

4) after reaching design height.

2, use notice:

1) the operational layer on the construction load should comply with the design requirements, shall not be overloaded;

2) shall not be templates support, cable wind rope, pumping concrete pipe fixed on the scaffolding, prohibit any suspension hoisting equipment;

3) cet 6 and cet 6 or more high winds and fog, rain should stop scaffold work, after the rain on operating slippery measure should have.

4) during the period of scaffolding used, it is strictly prohibited to dismantle the following bar: the master node in vertical and longitudinal rod, longitudinal and transverse rod sweeps the floor;

5) connect the wall rod support;To dismantle the above any member shall take safety measures, and the competent department for approval.Based and adjacent mining operations are strictly prohibited in the scaffold, or security measures should be taken, and the project manager and the full-time security officer for approval.

6) on the scaffolding, when electricity, gas welding, must have a fire prevention measures and personnel guards;

7) scaffold for site erection of temporary electricity lines and grounding, lightning protection measures shall be carried out according to the current national standard.

Nine, scaffolding demolition of safety technical measures

1, receives the project department dismantled scaffold frame body plan descriptions of the rear can work on.Before disassembly, comprehensive review intends to dismantle scaffold fastener connection, even the wall parts, support system is in line with the requirement.According to the results of the inspection work out production plan, submitted to the approval of technical clarificaiton after work.Work plan generally includes: down the steps and methods, safety measures, materials piled up in the place, labor organization arrangement.

2, dismantle scaffold on the ground and debris should be removed before obstacles, and then divided into areas, a rope tied around the fence or hang eye-catching warning signs, the ground should be designated persons command.Operators are strictly forbidden in the alert area of passage or continue at the bottom of the scaffolding construction, monitoring personnel to perform their duties, equipped with good communication device.

3, dismantled before should be dismantled by unit, head of the engineering safety technical disclosure.Demolition of the high places of the workers should wear safety helmet, wearing a seatbelt, chaps, wearing non-slip shoes.

4, carefully check the lifting machinery including fixture is safe, reliable and set-up on the scaffolding, lifting machinery is not allowed to set up the Settings.

5, after the demolition of personnel into the post, first check to reinforce the loose parts, step remove the materials, items and stay inside the garbage, clean up all the content security to the ground, it is strictly prohibited to high toss.

6, scaffolding demolition process: put safety net - vertical scaffold board - pad scaffolding plank, guardrails, joists, scissors poles, even the wall bar, longitudinal bar, lateral horizontal pole - post - bottom line of longitudinal rod, joists, flat bar, diagonal brace.(that is, to build after the demolition, after a demolition on the order of the first, and each step once a clear principle. It is strictly prohibited and disassemble frame work at the same time.)

7, tear open poling, want to embrace poling first, then open two buttons.Demolition of longitudinal rod, brace, bracing, should first open the middle buckle, then hold the middle, to solve the end button again.

8, connecting rod (nodes) should be with dismantling progress step by step a demolition, forbidden to connect a whole wall layer or layers is dismantled in dismantle scaffold;Segmented demolition of elevation difference should not be more than two steps, such as the elevation difference is greater than two steps should add the wall a reinforcement;When the scaffold to lower down the last long when the height of the stud, should be in place to build temporary cast after reinforcement, demolition of the wall again.When the scaffolding to staging, discrete surface removal, for not dismantle scaffold at both ends, should be stipulated in the standard setting wall and lateral brace with reinforcement.

Ten, scaffolding demolition of safety management

1, demolition work must be carried out step by step a top-down and do not allow the discrete surface to dismantle or upper and lower two step removed at the same time, serious do it step by step, a rod.

2, all the wall rod, scissors pole pieces, vertical plate, high insulation measures must be demolished with scaffolding step layer synchronously.No first dismantled.Segmented dismantling height should not be more than two steps, such as the elevation difference is more than two steps, should add the wall reinforcement.

3, all bar and fasteners, separation when removed, do not allow the bar on the fastener to the ground or two at the same time remove the ground.

4, put all scaffolding plank to dismantle, raise the carrying, the outgoing to prevent from the inside out.Scaffolding is forbidden on the garbage objects directly from the high fall injury.

5, after the completion of the day, carefully check posts around the situation, such as finding hidden danger, timely repair or continue to finish to a program, a part of the end, may leave post.

6, dismantle to a unified command, echoed up and down, coordination, when untied the knot buttons associated with another person, should first notify the other party, in case of falling.

7, when the demolition of frame collision scaffold near the power cord, is strictly prohibited to prevent electric shock accident.

8, when the demolition, not to change horses in the middle of the stream, if must change, should be disabled account rear can leave.

9, remove the material to slowly next shipment, it is forbidden to throw to the ground.To the components of the ground should be timely inspection, repair and maintenance, as stipulated in the specification and code heap to store at any time according to the varieties, specifications.

Eleven, fastener type steel pipe scaffold design calculation

Fastener type steel pipe scaffold landing calculation on the basis of the construction fastener type steel pipe scaffold safety technical specifications "(JGJ130-2011), the specifications for design of building foundation (GB50007-2011)," load code for the design of building structures "(GB 50009-2012), the specifications for design of steel structures (GB50017-2003), etc.

A), the parameter information

1. The scaffold parameters

Double row scaffolding, height of 11.6 m;

Erection of size for: horizontal distance Lb is 1.05 m, throw La is 1.55 m, large lateral horizontal bar step distance of 1.54 m;

Within the shelf from the wall length of 0.15 m;

Lateral horizontal pole, on lap on the longitudinal rod lateral horizontal pole number for 3 root;

Scaffolding along the wall longitudinal length is 120.00 m;

The steel pipe type for Φ 48 x 3.0;

Rail and vertical connection mode for the fasteners;Take fastener against sliding bearing capacity coefficient of 1.00;

Even the wall with two step three spans, the vertical spacing of 3.08 m, 4.65 m horizontal spacing, connected by fasteners;

Even the wall of a connection for the fasteners;

2. The live load parameters

Construction of uniform live load standard values: 3.000 kN/m2;Scaffolding purpose: structure of the scaffold;

At the same time the construction layer, layer 2;

3. Wind load parameters

This project is located in shandong zibo Zhang Dian, the basic wind pressure 0.4 kN/m2;

Coefficient of wind load height change mu z, JiSuanLian strength, when the wall take 0.92, take 0.74 when calculating poling stability, wind load shape coefficient of 0.214 mu s;

4. Static load parameters

Poling under the weight of per meter standard (kN/m) : 0.1391.

Scaffolding weight values (kN/m2) : 0.300.Railing against my standard weight (kN/m) : 0.150.

Safety facilities and safety net (kN/m2) : 0.005.

Scaffolding categories: bamboo basketry scaffold board;Rail baffle categories: bamboo basketry scaffolding baffle;

Scaffolding steel pipe standard weight per meter (kN/m) : 0.033.

Scaffold board laid to the total number of layers: 13;

5. The foundation parameters

The foundation soil types: grain filling;Standard value of subgrade bearing capacity (kPa) : 150.00;

Poling foundation bottom surface area (m2) : 0.20.The adjustment coefficient of subgrade bearing capacity: 1.00.

2), the calculation of lateral horizontal bar

Lateral horizontal rod according to the calculation of strength and deflection of simply supported beam, the lateral horizontal bar on the top of the longitudinal bar.

According to the above the lateral horizontal pole as a uniformly distributed load of scaffold board and live loads calculating the maximum bending moment and deformation of the lateral horizontal bar.

1. The uniformly distributed load value is calculated

Lateral horizontal bar of the weight of standard values: P1 = 0.033 kN/m;

Scaffolding load standard values: P2 = 0.3 x 1.55/4 = 0.116 kN/m;

Live load standard values: Q = 3 x 1.55/4 = 1.162 kN/m;

The calculated value of load: q = 1.2 x 0.033 x 0.116 + 0.116 + 0.033 * 1.162 = 1.807 kN/m;

2. The strength calculation

Maximum bending moment consider for simply supported beam under the action of uniformly distributed load bending moment,

Computation formula is as follows:

Mqmax=ql2/8

Maximum bending moment Mqmax = 1.807 x 1.052/8 = 0.249 kN m.;

Maximum stress calculation sigma = Mqmax/W = 55.461 N/was;

Lateral horizontal pole the maximum bending stress of sigma = 55.461 N/was less than transverse bending strength design value of the horizontal pole [f] = 205 N/was, meet the requirements!

3. The deflection calculation

Considering the maximum deflection for beam deflection under the action of uniformly distributed load

Load standard values of q = 0.033 + 0.116 + 1.162 = 1.312 kN/m;

Argument qmax = 5 ql4/384 ei

Maximum deflection argument = 5.0 * 1.312 * 10504 / (2.06 x 105 x 384 x 384) = 0.935 mm;

Lateral horizontal bar of the maximum deflection is less than 0.935 mm lateral horizontal bar of the maximum allowable deflection 1050/150 = 7 to 10 mm, meet the requirements!

3), the calculation of longitudinal bar

Longitudinal rod according to the three span continuous beam intensity and deflection calculation, lateral horizontal bar on the top of the longitudinal bar.

1. Load value is calculated

Lateral horizontal bar of the weight of standard values: P1 = 0.033 * 1.05 = 1.05 kN;

Scaffolding load standard values: P2 = 0.3 * 1.05 * 1.55/4 = 0.122 kN;

Live load standard values: Q = 3 * 1.05 * 1.55/4 = 1.221 kN.

Load design value: P = (1.2 x 0.035 x 0.122 + 0.122 + 0.035 x 1.221) / 2 = 0.949 kN.

Longitudinal bar diagram calculation

2. The strength calculation

Maximum bending moment consider for longitudinal rod weight of uniformly distributed load and lateral horizontal rod load transferring the design of the value of the bending moment and the most unfavorable allocation.

Mmax=0.08ql2

Uniformly distributed load maximum bending moment calculation: M1max = 0.08 * 0.033 * 0.033 * 1.55 = 0.006 kN m.;

Concentrated load formula of maximum bending moment is as follows:

Mpmax=0.417Pl

Concentrated load maximum bending moment calculation: M2max = 0.417 * 0.949 * 0.949 = 0.613 kN m.;

M=M1max + M2max=0.006+0.613=0.62kN·m

Maximum stress calculation sigma = 0.62 x 106/4490 = 137.987 N/was;

Longitudinal bar of maximum bending stress calculation sigma = 137.987 N/was less than the longitudinal bending strength design value of the horizontal pole [f] = 205 N/was, meet the requirements!

3. The deflection calculation

Maximum deflection considering for longitudinal rod weight of uniformly distributed load and lateral horizontal rod load transferring the design of the value of the deflection and the most unfavorable distribution, unit: mm;

Uniformly distributed load maximum deflection calculation formula is as follows:

Argument Max = 0.677 ql4/100 ei

Longitudinal rod weight of uniformly distributed load maximum deflection caused by:

Argument Max = 0.677 * 0.033 * 15504 / (2.06 x 105 x 100 x 100) = 0.059 mm;

Concentrated load maximum deflection calculation formula is as follows:

Argument pmax = 3.029 Pl3/100 ei

The most unfavorable distribution of maximum deflection caused by concentrated load standard values:

P=(0.035+0.122+1.221)/2=0.689kN

Argument = 3.029 * 0.689 * 15503 / (2.06 x 105 x 100 x 100) = 3.499 mm;

Maximum deflection and: argument argument Max + argument pmax = 0.059 + 3.499 = 3.557 mm;

Longitudinal bar the maximum deflection of the 3.557 mm less than the maximum permissible deflection of longitudinal rod 1550/150 = 10.3 to 10 mm, meet the requirements!

4), fasteners, sliding resistance calculation

Construction fastener type steel pipe scaffold safety in accordance with the technical specification training seminars, liu editor, P96 page, double fastener bearing capacity design value of 16.00 kN, according to the fastener against sliding bearing capacity coefficient of 1.00, and the engineering practice of rotating double fastener bearing capacity value of 16.00 kN.

Vertical or longitudinal rod connected to the stud, anti-sliding bearing capacity calculated according to the type of fastener (" construction fastener type steel pipe scaffold safety technical specifications "5.2.5) :

R ≤ Rc

The Rc - fastener against sliding bearing capacity design value, take 16.00 kN.

R - vertical or longitudinal rod to stud the vertical force design values;

Lateral horizontal bar of the weight of standard values: P1 = 0.033 * 1.05 * l = 0.052 kN;

Longitudinal bar of the weight of standard values: P2 = 0.033 * 1.55 = 1.55 kN;

Scaffolding standard weight: P3 = 0.3 * 1.05 * 1.55/2 = 0.244 kN;

Live load standard values: Q = 3 * 1.05 * 1.55/2 = 2.441 kN.

The design of the load value: R = 1.2 * (0.052 + 0.052 + 0.244) + 1.4 * 2.441 = 2.441 kN;

R < 16.00 kN, so the bearing capacity of double fastener anti-sliding design meet the requirements!

5), scaffolding rod load calculation

Role in the load of scaffold including static load, live load and wind load.Static load standard values include the following contents:

(1) per meter poling under the weight of the standard, 0.1391 kN/m

NG1=[0.1391+(1.05×3/2)×0.033/1.54]×24.00=4.156kN;

(2) scaffold board weight standard;Using bamboo basketry scaffolding, standard value of 0.3 kN/m2

NG2= 0.3×13×1.55×(1.05+0.1)/2=3.627kN;

(3) the railing and scaffold board weight of the standard;Using bamboo basketry scaffolding baffle, standard value of 0.15 kN/m

NG3=0.15×13×1.55/2=1.511kN;

(4) hanging load safety facilities, including safety net: 0.005 kN/m2

NG4=0.005×1.55×24=0.186kN;

After calculated, static load standard values

NG=NG1+NG2+NG3+NG4=9.48kN;

Live load for the axial force produced by the construction load standard values sum, poling as one half of the total construction load in the longitudinal spacing values.After calculated, live load standard values

NQ=3×1.05×1.55×2/2=4.882kN;

Considering the wind load, the stud design value of the axial pressure

N=1.2 NG+0.85×1.4NQ=1.2×9.48+ 0.85×1.4×4.882= 17.186kN;

Regardless of the wind load, the rod design value of the axial pressure

N'=1.2NG+1.4NQ=1.2×9.48+1.4×4.882=18.212kN;

6), the stability calculation of stud

Outside scaffolding set-up part adopts double stud, set according to requirements of the structure, stability calculation, only ChanLi rod stability calculation.

Wind load standard values according to the following formula

Wk = 0.7 mu, mu z s. a omega zero

The omega 0 - basic wind pressure (kN/m2), in accordance with the "load code for the design of building structures" (GB50009-2012) using: omega 0 = 0.4 kN/m2;

Mu z - coefficient of wind load height changes, according to the "load code for the design of building structures (GB50009-2012) using: mu z = 0.74;

Mu s -- wind load shape coefficient value is 0.214;

After calculated, wind load standard values for:

Wk=0.7 ×0.4×0.74×0.214=0.041kN/m2;

Wind load design value of vertical pole bending moment MW as follows:

Mw=0.85 ×1.4WkLah2/10=0.85 ×1.4×0.041×1.55×1.542/10=0.018kN·m;

Considering the wind load, the stability of the stud calculation formula

Sigma = N/(phi A) + MW/W or less [f]

Poling axis pressure design value: N = Nd = 17.186 kN;

Regardless of the wind load, the stability calculation formula of stud

Sigma = N/(phi A) [f] or less

Poling axis pressure design value: N = N '= 18.212 kN.

Calculation of poling section radius of gyration: I = 1.59 cm;

Calculated length coefficient of additional reference to the construction fastener type steel pipe scaffold safety technical specifications "(JGJ130-2011) table 5.3.3: k = 1.155;

Calculated length coefficient with reference to the construction fastener type steel pipe scaffold safety technical specifications "(JGJ130-2011) table 5.3.3: mu = 1.5;

Calculate length, be determined by formula l0 = kuh: l0 = 2.668 m;

Slenderness ratio: L0 / I = 168;

The stability factor of axial compression poling phi, the slenderness ratio of lo/I look-up table the result: phi = 0.251

Poling net section area: A = 4.24 cm2;

Poling net section modulus (resistance moment) : W = 4.49 cm3;

Steel stud compressive strength design values: [f] = 205 n/was;

Considering the wind load

Sigma = 17186.191 / (0.251 x 424) + 17941.773/4490 = 165.484 N/was;

Poling stability computing sigma = 165.484 N/was less than the compressive strength of stud design value [f] = 205 N/was, meet the requirements!

Regardless of the wind load

Sigma = 18211.516 / (18211.516 x 424) = 171.122 N/was;

Poling stability computing sigma = 171.122 N/was less than the compressive strength of stud design value [f] = 205 N/was, meet the requirements!

7), the largest build-up height calculation

According to the technical specification for construction fastener type steel pipe scaffold safety (JGJ130-2011) article 5.3.6 considering wind load, adopting ChanLi tube open, closed and semi-closed scaffolding set-up height can be calculated according to the type:

NG2k Hs = [phi Af - (1.2 + 0.85 x 1.4 (Σ NQk + Mwk phi A/W))] / 1.2 Gk

Components weight of the axial force produced by standard NG2K (kN) calculation formula is:

NG2K=NG2+NG3+NG4=5.324kN;

Live load standard values: NQ = 4.882 kN;

Poling under the weight of per meter standard: Gk = 0.139 kN/m;

Calculate vertical pole bending moment produced by wind load standard values: Mwk = Mw/(1.4 x 0.85) = 0.018 / (1.4 x 0.85) = 1.4 kN m.;

Hs =( 0.251×4.24×10-4×205×103-(1.2×5.324+0.85×1.4×(4.882+0.251×4.24×100×0.015/4.49)))/(1.2×0.139)=55.071 m;

According to the technical specification for construction fastener type steel pipe scaffold safety (JGJ130-2011) article 5.3.6 scaffolding, Hs is equal to or greater than 26 meters high, according to the adjustment and not more than 50 meters:

[H]=Hs /(1+0.001Hs)

[H]=55.071 /(1+0.001×55.071)=52.196 m;

[H] = 52.196 compared with 50 smaller value.After calculated, scaffolding, height limit [H] = 50 m.

Scaffolding set-up highly ChanLi rod to 0 m, less than [H], meet the requirements!

Eight), and even the stability of the wall of a calculation

Even the wall of the axial force design values should be calculated according to the type:

Nl=Nlw + N0

Even the wall of a wind load standard values calculated on scaffold height mu z = 0.92, mu s = 0.214, 0 = 0.37 omega,

Wk = 0.7 mu, mu z s. a omega 0 = 0.7 * 0.92 * 0.92 * 0.37 = 0.051 kN/m2;

Within the area covered by each even wall pieces scaffolding the outside of the windward area of Aw = 14.322 m2;

According to the technical specification for construction fastener type steel pipe scaffold safety (JGJ130-2001) article 5.4.1 wall constraint the scaffold with out-of-plane deformation produced by the axial force (kN), N0 = 5.000 kN.

Even the axial wall force produced by the wind load design value (kN), calculated according to the type:

Nlw=1.4×Wk×Aw=1.022kN;

Even the wall of the axial force design values Nl = Nlw + N0 = 6.022 kN;

Even the wall bearing capacity design value press type calculation:

Nf = phi a. [f]

The phi - axial compression poling stability factor;

By the result of the slenderness ratio l/I = 150/15.9 look-up table phi = 0.976, l is the length of the bent frame wall from;

A=4.24 cm2;[f]=205N/mm2;

Even the axial wall bearing capacity design value of Nf = 0.976 * 4.24 * 10-4 x 205 x 103 = 84.834 kN.

Nl = 6.022 < Nf = 84.834, and even the wall design meet the requirements!

Even the wall with double buckle connected to the wall.

Nl = 6.022 is less than the calculated from the above 16 kn double sliding resistance of fastener, meet the requirements!

Even the wall of a fastener connection diagram

9), the foundation bearing capacity calculation of stud

Stud base underside of average pressure should meet the requirements of the type

p ≤ fg

Design value of subgrade bearing capacity:

fg=fgk×kc=150 kPa;

Among them, the standard value of subgrade bearing capacity: FGK = 150 kPa;

Scaffolding foundation bearing capacity adjustment coefficient: kc = 1;

Poling bottom of foundation of average pressure: p = N/A = 89.927 kPa;

On the surface of the upper structure to the foundation top axial force design values: N = N + 0.033 x H1 = 17.186 + 0.033 x 24 = 17.985 kN.

The bottom of foundation area: A = 0.2 m2.

P = 89.927 kPa fg = 150 kPa or less.Meet the requirements of subgrade bearing capacity.

Technical supportúXiamen 12T Network Technology Co. Ltd. Talent supportu :Xiamen Talent Network

Technical supportúXiamen 12T Network Technology Co. Ltd. Talent supportu :Xiamen Talent Network